Underseals and restoration work is very much an everyday thing here at Slide Motorsport, we thought we would give a little bit of break down. The jobs vary massively due to vehicle type and usen, budget comes into it hugely and often so do time restaints however the info below covers the basics…

Assess the job

First step is always to assess the job, we like to see the car in person on the ramp where we can talk through with you, the customer on exactly what is needed and what we recommend and work out some costs and prices.

Strip down

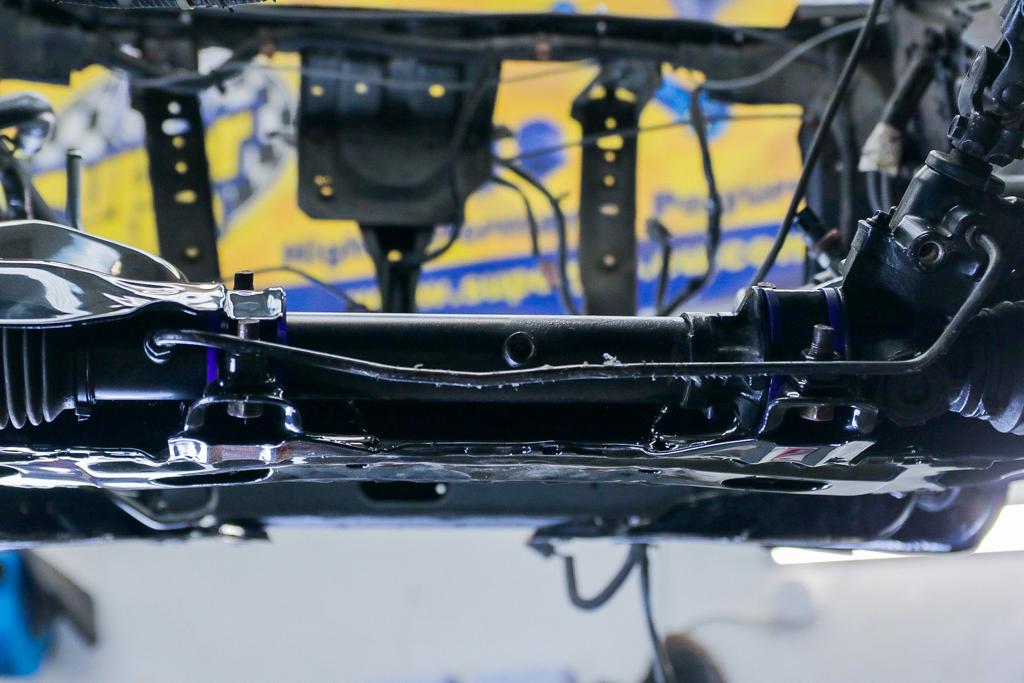

Once the vehicle is with us to actually start the job we can start the strip down process, removing either the basics like the exhaust, heat shields, wheels, arch liners etc or if its a complete job then the subframes, suspension, fuel tank and all lines.

Clean up

The not so fun part, all the dirt and old underseal needs to be removed, using a number of tools and hard work the clean metal starts appearing. Any surface corrosion is treated using hydrate 80 solution which is one of the best on the market.

Welding

Not many places in the UK still carry out bespoke high level welding on vehicles, many can do patch work for MOT’s but making new factory sections and welding them in so they look OEM spec is a different ballgame. We have a great team with years of experience doing this. There are many steps in this process that are so important, like treating not only the areas visible on the outside but also the inside as it’s a well known fact a lot of cars rust from the inside outwards.

Prime

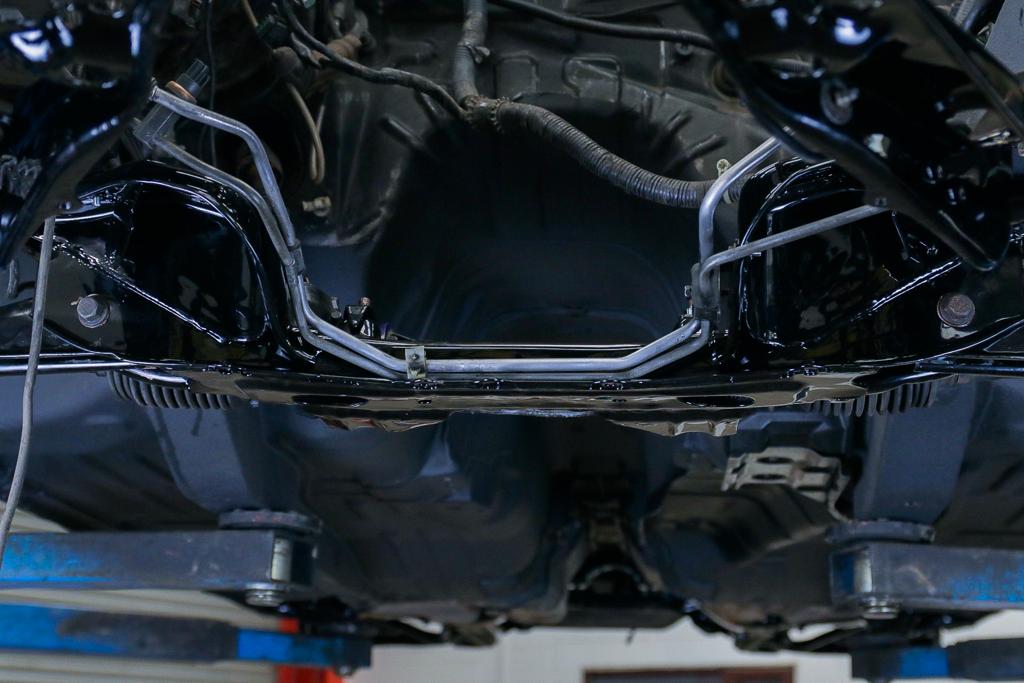

Once the shell is solid again and free of any rust the fun part begins, the first step of that is getting primer on the underside, we use special anti corrosive primer to protect the car as we have found that this produces the best results possible!

Seam seal

It’s really important to seal up all the panels where needed to stop any water getting between the panels or anywhere else it shouldn’t. But just as important is to leave certain gaps to allow water to drain and parts to breath. There are plenty of other little tricks to really maximise the cars life, these come from years of experience.

Underseal

After all the hard work it’s time to get the Gravitex on which is our underseal of choice! We will happily use different products if asked but Gravitex is our go to product to seal it all up. It is also overpaintable, it is becoming ever more so common for us to then add another coat of paint which gives it even more protection, makes it easier to wipe clean and of course it can literally be whatever colour you like!!

Rebuild

It’s the home straight now, all the bits we removed can be refitted. Now the shell is super clean it is sometimes a shame to put old worn and sometimes rusty parts back on. Many people choose now to either replace, upgrade or let us strip the parts, refurbish, powder coat, fit new bushes and arms etc before refitting them to the car.

We have done this process on vans, 4×4’s, new cars, old cars and classics. Professional undersealing often adds value to the vehicle and most importantly stops them rusting to death so you able to get many years of pleasure or functionality from them!!

If you have any questions or would like a qoute then don’t hesitate to get in touch with the team and we’ll do our best to look after you. We also welcome anyone interested in services like this to arrange coming down to our workshop to see the high standards we work too.